Plain Bearing PV

Notes & Use

Calculates design values (velocity, force, and combined) of plain bearings when the following are true:

- For radial (journal) applications

- the bearing rotates around a shaft,

- the rotational motion is continuous (as opposed to an ocillating),

- the load is applied perpidicular to the axis of rotation (radial).

- For thrust applications:

- the load rotates upon the bearing, around a fixed center point,

- the thrust bearing’s bearing surface is circular or annular,

- the rotational motion is continuous,

- the load is applied parallel to the axis of rotation,

- the load is uniform across the surface area of the bearing.

This calculator does not address any issues beyond P, V, and PV calculations, such as:

- Effects of friction,

- Additional heat and energy-dispersal concerns,

- Dimensional changes due to heat deformation,

- Tribology/lubrication concerns,

- including cleanliness and suitability of lubricants

- Wear factors

- Operating Temperatures

- Lifetime calculations

- Shock-load and impact factors

Calcuations

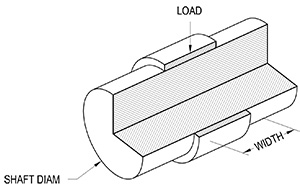

Radial Figure

Radial Terms

$L$ = load on bearing, pounds force

$n$ = Shaft speed, rotations per minute

$d$ = Diameter of shaft (ID of bearing), inches

$w$ = Bearing width, inches

$P$ = Pressure on bearing, psi

$V$ = velocity of bearing surface, feet per minute

$PV$ = Pressure × Velocity

Radial Equations

$$ P_{actual} = \frac {L} {w d} $$

$$ V_{actual} = \frac {n d \pi} {12} $$

Thrust Figure

Thrust Terms

$L$ = load on bearing, pounds force

$n$ = Rotation speed, rotations per minute

$d$ = Inner diameter of bearing’s surface area, inches

$D$ = Outer diameter of bearing’s surface area, inches

$P$ = Pressure on bearing, psi

$V$ = velocity of bearing surface, feet per minute

$PV$ = Pressure × Velocity

Thrust Equation

$$ P_{actual} = \frac {4L} {\pi (D^2 - d^2)} $$

$$ V_{actual} = \frac {n \left( \frac{D - d}{4} \right) \pi} {12} $$

Pass/Fail Test

$P_{actual}$, $V_{actual}$, and $PV_{actual}$ are compared to the respective allowable values:

- Pass = actual < allowable

- Fail = actual ≥ allowable

Material P, V, and PV values

The design values provided by the drop-down material box are culled from various sources, notably Mcmaster-Carr and Wikipedia. A full table of those values is as follows:

| Material | P | V | PV |

|---|---|---|---|

| psi | fpm | psi×fpm | |

| SAE 841 | 2,000 | 1,200 | 50,000 |

| Graphite SAE 841 | 1,600 | 1,000 | 40,000 |

| SAE 660 | 4,000 | 750 | 75,000 |

| SAE 841 | 2,000 | 1,200 | 50,000 |

| SAE 863 | 4,000 | 225 | 35,000 |

| Nylon | 400 | 360 | 3,000 |

| Nylon MDS #1 | 2,000 | 393 | 3,400 |

| UHMWPE | 1,000 | 100 | 2,000 |

| Acetal | 1,000 | 1,000 | 2,700 |

| Ptfe | 500 | 100 | 1,000 |

| Ptfe (glass filled) | 1,000 | 400 | 11,000 |

| Rulon 641 | 1,000 | 400 | 10,000 |

| Rulon J | 750 | 400 | 7,500 |

| Rulon LR | 1,000 | 400 | 10,000 |

| Peek (blend 1) | 8,500 | 400 | 3,500 |

| Peek (blend 2) | 21,750 | 295 | 37,700 |

| Vespel | 4,900 | 3,000 | 30,0000 |

Sources

- Robert L. Mott, Machine Elements in Mechanical Design, 4th ed. pp. 669, 2003.

- Dupont Vespel Design Guide

- Mcmaster-Carr

- Wikipedia